Transfer stamping tools, unlike progressive tools, allow greater freedom of movement, offering the possibility of forming more complex and larger parts. LOIRE ETUDE is involved in the entire process, design to production of our transfer stamping tools. We also design the transfer system, made up of side bars equipped with grippers. These allow various stamping operations to be carried out simultaneously. All our transfer systems are simulated on Kinematics software, and verified on the workshop test bench.

LOIRE ETUDE specialises in large-scale tools and in particular in the stamping of aluminum and very high elastic limit steels (such as DP800 & DP1000) For all new transfer tool projects, LOIRE ETUDE assists its customers in reducing material commitments, by virtue of co-engineering from project development to commissioning. In addition, we can guide you through the transition from transfer stamping to progressive stamping tools, offering higher added value and better results.

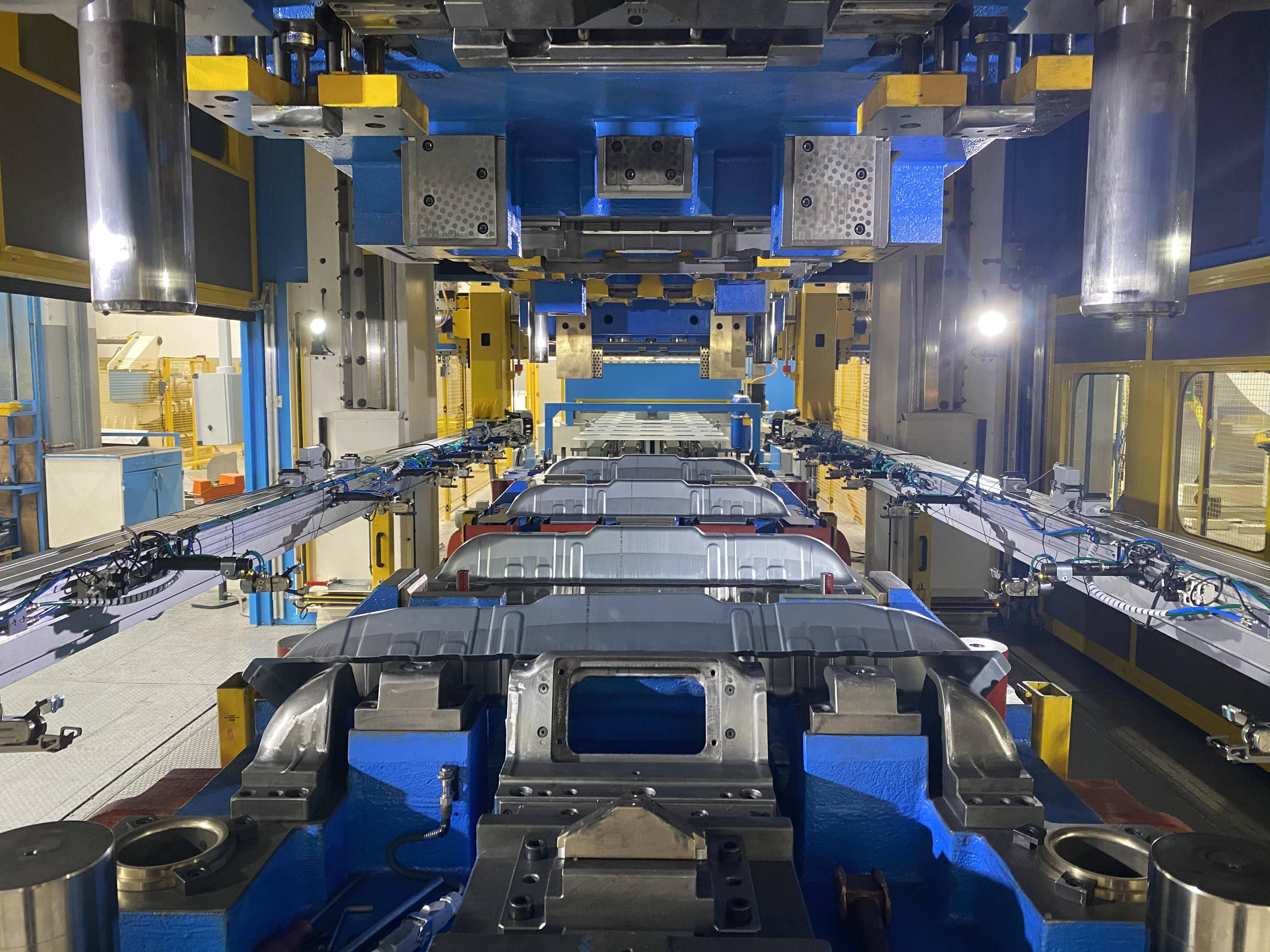

- Operations : 5

- Material : DP780 / Thickness : 1,15 mm

- Prestation : Process, die design, tool manufacturing & home line tryout

- Dimensions : M1 = 1950*1770*930 mm

M2 = 3100*1870*930 mm

Total : 5050mm long

- Tool cadence : 18 strokes/min