5-axis machining of up to 9 meters and lifting up to 80 tons

.

Designer and manufacturer of large-scale materials forming tools, Loire Etude supports its customers in reducing CO2 emissions and optimising production costs. This involves optimising material commitments and developing new technologies.

5-axis machining of up to 9 meters and lifting up to 80 tons

45 employees

Export to more than 15 countries

Press fleet with a power of 400 to 1250 tons

Certifications:

ISO 9001, 14001, 45001

Annual Budget : 1 000 000 €

QUALITY

INDUSTRIAL PERFORMANCES

Innovation

EXPERTISE

The pursuit of quality is one of Loire Etude's core values. Achieving the objective is made possible thanks to constant improvements in performance (notably with tool manufacturing automation), which remains a major challenge for unitary manufacturing. Innovation is a central pillar of our activities. No less than 7% of annual turnover is devoted to R&D. Finally, Loire Etude places great importance on sharing its expertise. 10% of our workforce are apprentices, and we continuously train young people in the tooling, machining or engineering trades, in order to maintain a high level of expertise we have demonstrated for over 50 years.

Our family business places people at the heart of its projects and strives to maintain our values of consensus, respect and team spirit. Our values, just as much as technical skill or industrial know-how, contribute to our success. Each employee receives continuous professional development in new technologies and working methods. Continually seeking dynamic partners, Loire Etude invites you to join us and discover the opportunities we have to offer.

Founded in 1966 in the town of Chasse sur Rhône (south-east France), the company specialised in the design & manufacture of stamping tools (transfer & progressive) intended for the household appliance industry. Very quickly, LOIRE ETUDE developed and diversified its activities, entering the automotive sector

After 30 years, Loire Etude undertook a change of direction with the takeover of the company by Michel Garson. The company strengthened its presence in the automotive industry, particularly among French manufacturers. This strategy payed off and Loire Etude continued to progress. Thanks to this rapid development, the company moved in Saint-Chamond in 2000, having built a new factory in order to increase its industrial capacity.

This period witnessed Loire Etude's growing renown in Europe, as it began exporting to the German market and collaborating with prestigious clients such as Audi and Daimler. Concurrently, the company continued its proactive approach, confirming its culture of developing innovative proposals. Loire Etude was elected PSA's best supplier in 2009 for its co-engineering work overhauling PSA's specifications.

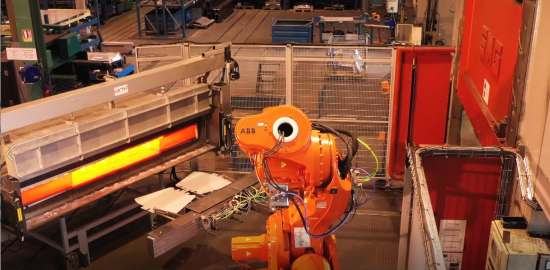

Following the global economic crisis, LOIRE ETUDE took a new strategic direction with the aim of adapting to the new economic and technical constraints. The main objective became capitalising on Loire Etude's unique expertise to engage with new customers and markets. As part of this strategy, the company brought its experience to new sectors such as aeronautics, agriculture and construction, and developed new technologies, such as hot forming and magnetic pulse forming. Loire Etude invested 2 million euros in hot stamping technology, enabling it become a leading European expert today.

LOIRE ETUDE is successfully pursuing its strategic direction, increasing its export rate from 22% to 70%. The diversification sought by the company has proven successful, particularly due to our collaboration with the aeronautics sector, which now represents 20% of our activity. Maxence Garson joined LOIRE ETUDE in 2015. This desire for continuous improvement which drives the company, lead us to invest 3.5 million euros between 2015 and 2020 in new systems, such as an imposing 5-axis (9*4m), very high-speed machining center, lifting capacity of 80 tons, a robotic cell for hot stamping, and a 3D scanner.